What We Do Best - Our Services

Excellent Communication, Cost Reduction, Seamless Transition to Supply Chain, and a loyal commitment to your success.

Smarter Sourcing. Superior Results.

Why Top Manufacturers Choose Alpha Resources

When it comes to aluminum extrusion, fabrication, and finishing, we’re more than a vendor, we’re your production partner. Companies across aerospace, construction, and OEM manufacturing trust us for one reason: we deliver consistent quality, fast turnaround, and real engineering support when it matters most.

- On-time delivery, batch consistency, and scalable output

- Cost-efficient aluminum sourcing without quality tradeoffs

- Full-service project management across extrusion, fab, and finish

- Flexible solutions tailored to your spec, timeline, and budget

Renewable Energy

Solar Panel Frames and Mounting Systems

Structural Supports for Renewable Installations

Thermal Management Components

Wind Turbine Components

Energy Storage and Battery Components

And More

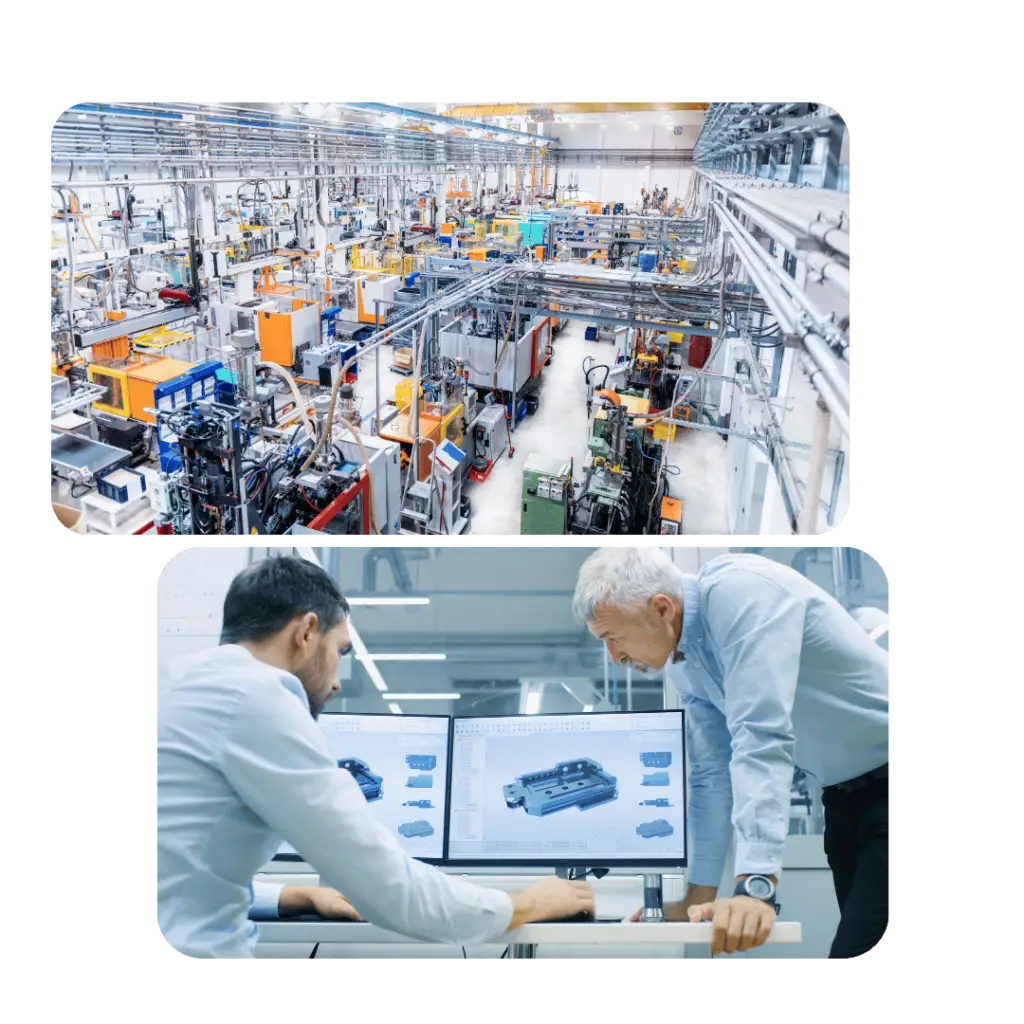

Industrial Solutions

Custom Machine Parts

Electrical Housing

Factory Infrastructure

Heavy Equipment Components

HVAC Applications

Electrical Housing & More

Architectural Sector

Storefront - Curtain Wall

Window & Door Frames

Railing Systems

Sunshades & Louvers

Structural Support

And Much More

Automotive Sector

Transportation Automotive Spaceframe

Interior and Exterior Trim

AC Components

Heatsinks

Weight Reduction

And More

Firearms

Scope Mounts

Rail Systems

Suppressor Components

Gun Frames and Receivers

Stock and Grip Components

Magazines and Housings

Quality & Certifications

US AAMA 611-12

US AAMA 2603

US AAMA 2604 + 2605

IATF16949

ISO 9000

We'll help design custom extrusions for fit, form, and function with cost in mind.

We provide unmatched value through competitive pricing, superior craftsmanship, value engineering, and exceptional service. Our dedication to precision, efficiency, and customer satisfaction sets us apart, ensuring your projects are completed on time and complete, within budget, and to exact specifications.

Projects & Application Samples

Our Fabrication Services

We turn raw aluminum extrusions into precision components, custom-fabricated to meet your exact specs. From complex profiles to tight tolerances and secondary operations like punching or drilling, we deliver production-ready parts built for performance.

Our Capabilities:

CNC Machining: Capable of up to 9-axis operations.

Precision Cutting: For extrusions up to 14' in length.

Punching and Tapping: Punching power up to 60 tons

Tube Deburring: Removing burrs and imperfections.

Welding: MIG and TIG capabilities

The Alpha Resources Newsletter

Leave your email below for market updates, news, and more!

Market News and Information

Prior Month Average in Dollars (USD) per Pound - 2024 ; 2025

No Data Found

- All

- Market News

Aluminum futures fell below $2,570 per metric ton ($1.166/Lb.), the lowest in ten weeks, as rising trade tensions and tariffs threaten global demand.

Learn how aluminum painting relies on a two-step process—pre-treatment and application—to achieve durable, high-performance finishes that meet AAMA standards.

Before you specify and pay too much, consider the difference and costs! The American Architectural Manufacturers Association (AAMA) Specification 611-12 outlines test procedures and minimum standard requirements for Class I and Class II anodic coatings. *Coatings should be visibly free of surface imperfections and color shift on exposed surfaces when observed from 10 feet or more.* *Data extracted from AAMA 611-12; MIL-A-8625F; ASTM test methods B 244-97, 487-85,...